Whenever we remove ice there’s always paint left behind. This is a pretty normal amount and takes a few days to clean up each year. We’re about halfway done with the removal process!

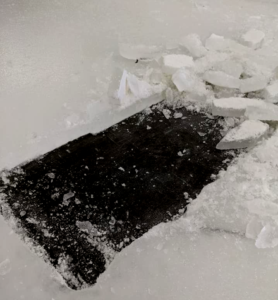

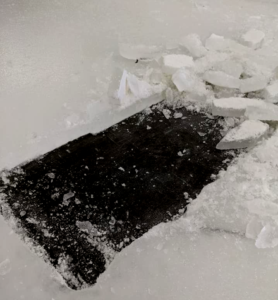

To start, we do a few tests and make sure that the bond is broken, then pounded this hole in the middle. Notice the white layer in the ice? That’s the paint we are trying to keep frozen.

Thanks to some beautiful weekend weather, the bond of the curling ice broke today and we started removing the surface. We tried a different technique this year where we started from the middle and worked outwards, which went really well and is something we will do in the future.

Starting from the middle, we first broke a hole in the surface by hand, using an ice pounder. It’s essentially an old, duller blade from the Olympia (ice resurfacer) that’s welded onto a bar and weighs 30-40 pounds. Once we have a hole started, a special sharpened blade on the tractor can get under the ice and peel it back. We’re trying to have the ice melted just enough to get under, but keep the layer of paint frozen in the ice so it doesn’t make a mess.

Once we broke the ice in the middle, we worked towards one end, all the way up to the hog line and houses. These are a textile logo, and fairly fragile, so we needed to use the pounder again and break the ice in thin layers above the colours so we don’t damage the logos.

To break all the ice around and on-top of the houses takes about an hour per house, though it went a bit faster this year as the new technique we used meant that there was always a broken section in front of the ice, which makes it much weaker.

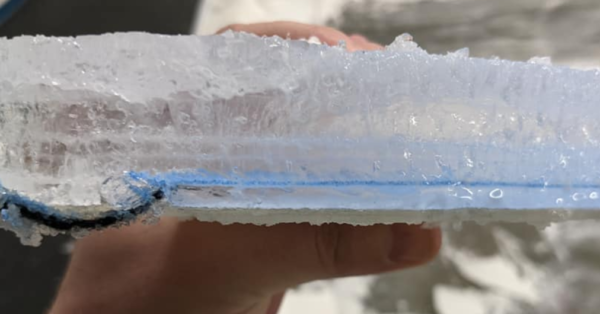

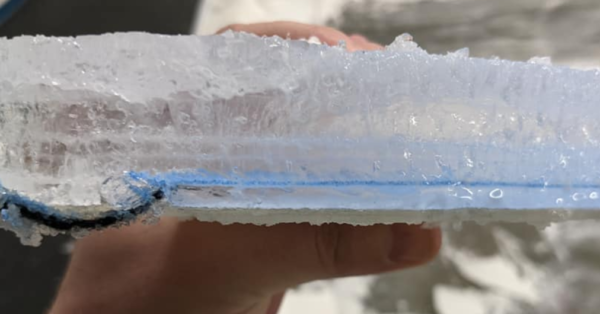

A cross-section of painted ice. The bottom is painted white and appears solid here. The next layer is red (this is where the rocks are put at the end of a game, not the house), and the thin black lines are yarn. |

|

We got half of the houses out in this day’s work, and will be doing the same process again tomorrow for the other side. Because it’s so warm out and we want to keep the ice at the right temperature, we are throttling the plant some more today to make sure it doesn’t melt too fast and we don’t walk into a mess tomorrow.

Next I’ll show you what we do to clean and put away all of the logos so they’re all ready for next year, and then it’s onto the big cleanup!

Latest posts by found on fb

(see all)

Wawa-news.com You can't hear the 'big picture'!

Wawa-news.com You can't hear the 'big picture'!